Industry Representatives: Kirsty Davies, Jennifer Trittschuh

The clothes washing process removes dirt particles and grease-like products by a synergistic combination of chemical action, thermal action and mechanical action. More action of one type can compensate, at least to some degree, for less action of another type (ex: if detergent is increased, wash time can be decreased.)

When describing mechanical action, the actual mechanisms for soil removal are garment-to-garment rubbing, within-garment rubbing and garment-to-washing machine drum-skin rubbing.

In the washing process customers are primarily concerned with soil removal1 from their garments, but they are also concerned with the "wear and tear" that the garments are subjected to. This is referred to as gentleness of action2. Gentleness of action results from the rubbing actions described above.

Wash Performance (WP) is the sum of the Soil Removal and Gentleness. Many wash parameters can be changed to increase soil removal but will simultaneously decrease gentleness of action. Trade-offs need to be made and balances struck so that the overall wash performance will be acceptable to the user.

Wash performance testing of a particular washing machine is performed under controlled conditions: Water temperature, detergent concentration, load composition, load size, soil type and wash program. Swatches of special fabrics are attached to garments to provide estimates of soil removal and gentleness of action. Thus the chemical and thermal actions are fixed, leaving a number of mechanical and wash program variables for F&P designers and developers to alter and improve Wash Performance.

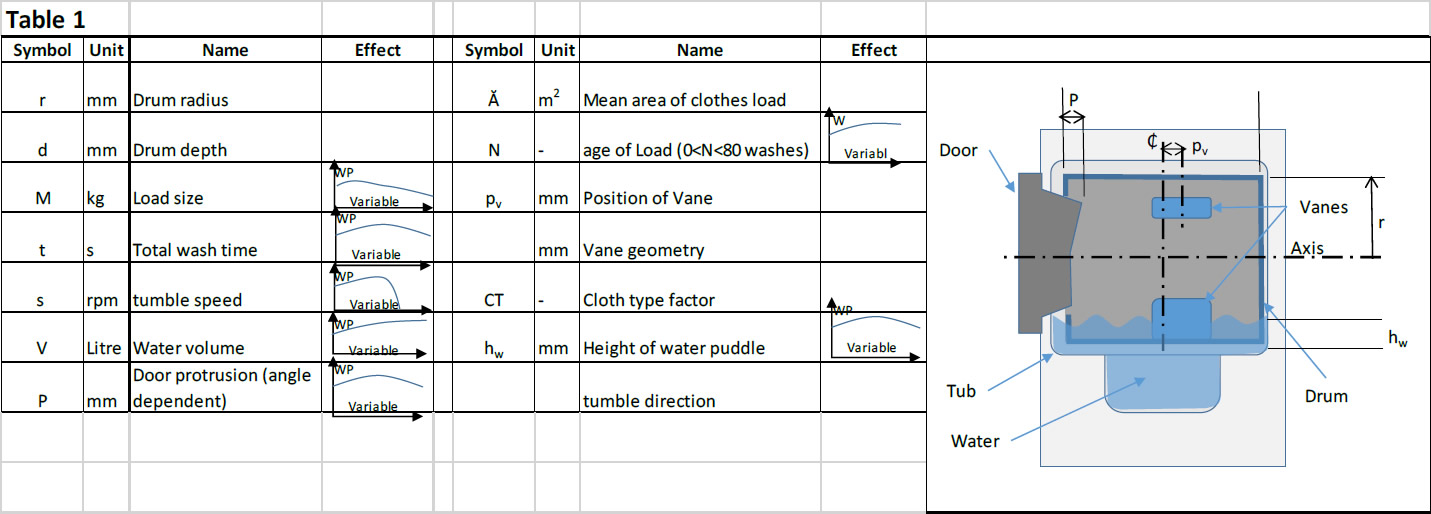

There are many mechanical and wash program variables involved (see a basic list in table 1, below).

1 Soil Removal

This is measured by the colour change of 20 or more "standardised dirt" cloth swatches after a wash cycle when compared to a "clean" standard swatch.

The Soil Removal is defined as two standard deviations less than the average colour change.

SR = Cmean – 2s

Figure 2: Soil removal swatches, before and after wash cycle

(top was heavy cycle; bottom was delicate cycle)

2 Gentleness of Action

This is measured by the amount of fray seen on 20 or so, 1dm squares of coarse-weave cloth after the wash cycle.

Figure 1: Gentleness of action (fray) swatches- before and after wash cycle

Table 1: Some variables affecting wash performance

Desired Outcomes:

While physical testing will always be part of our development regime, we would like to improve our designs

and reduce our development time by utilizing mathematical modelling. We would thus like to have a

mathematical model plus an efficient experiment plan so that we can develop the relationship between the

variables in Table 1 and wash performance. The model could be based on fundamental physics, empirical

statistics, dimensional analysis or some other method.

Demonstration Equipment:

- Front loading washing machine

- Videos showing differences in movement of different drum diameters and tumble speeds

- Appropriate clothes loads with colours that will show circulation

- Detergent

- Means for handling the water

Other Notes:

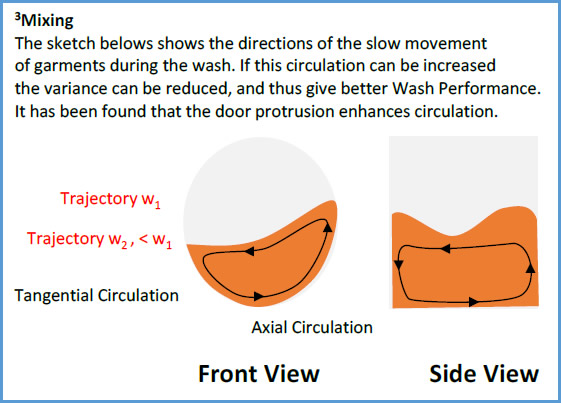

- There is variation in soil removal and gentleness of action and it is thought to be due to the variation in frictional rubbings (described above) across the load. Thus it would appear to be necessary to continually "mix3" the garments, so that the probability of each garment getting to each location in the drum is almost equal. This mixing seems to be a function of the circulation patterns shown.

- It has been shown that a protrusion at the top of the door has an effect on the circulation and thus on Wash Performance. This may be too complex to include in the model's first version but at a minimum, we would appreciate future proofing.

- One of our engineers thinks that Dimensional Analysis may be a way of developing the WP relationship. Table 2 shows his suggestions for some of the Dimensionless parameters. (This is provided as an option, not necessarily a preferred solution. We defer to your expertise to select the most appropriate model type.)

| Dimensionless Number |

Definition | Comment |

|---|---|---|

| π1 | d/r | Aspect Ratio usually between 1 & 2 |

| π2 | hv/r | Vane height |

| π3 | dv/d | Vane depth |

| π4 | pv/d | Vane position from centre of drum |

| π5 | P/d | Door Protrusion |

| π6,i | wi2r/g | Centripetal acceleration in units of [g] for the ith speed always<1 |

| π7 | Δw/√(g/r) | Speed range as a fraction of speed that gives 1g acceleration |

| π8 | ύt/V | Recirculating flow |

| π9 | V/(πdr2) | Water volume ratio to volume of drum |

| π10 | M/(ρwtrπdr2) | Clothes mass ratio to mass of drum full of water |

Glossary of Terms:

- Load composition: what types of items and fibres make up the load. Ex: sheets; towels; clothing; synthetics; cottons; baby clothes; table cloths; active wear;

- Load size: dry weight in kilos of load

- Soil type: description of the dirt present that the washing process is expected to remove. Ex: body oil and skin; charcoal; protein; wine;

- Gentleness of action: how much wear and tear a load is subjected to in a wash cycle. Quantified by the surface area of fabric swatches that has disturbed thread weaves at the end of a cycle.

- Soil removal: how much dirt is taken away from a load during a wash cycle. Quantified by the colour change in commercially-prepared pre-soiled fabric swatches from a wash cycle.